"In a design that suited the hospital''s severe space constraints, Zest WEG built the generator, transformer and remote radiator into special ISO shipping containers in a double-stack configuration," explained Johannes Nel, operations manager – production at Zest WEG. "The contract also included the refurbishment of the client''s existing 1 000 kVA 400V MTU open-type generator which was included in the solution."

The new genset expands the hospital''s standby generating capacity to 1 MVA continuous rating, allowing 100% of the institution''s functions to continue as normal during periods of load-shedding. Nel also highlights that reliable supply was key to the hospital''s safe and efficient operation, whether from mains or back-up supply.

To reduce the project lead time as much as possible, the delivery of certain imported components was arranged well in advance. The containerised solution was constructed and extensively tested at the Zest WEG genset manufacturing facility in Epping, saving time during installation.

"It was critical that any downtime be kept to an absolute minimum, as hospitals need to run continuously," Nel says. "With our expertise, product range and experience in the health sector, our design, installation and commissioning strategy was able to align closely with this priority."

A dry-type step-up transformer allows the generator to connect to the 11 kV council electricity supply council supply, which will reduce hospital downtime during commissioning. The resin-sealed transformer also provides a long-lasting solution with low maintenance and a high safety factor due to the absence of oil as a coolant.

Nel explains that another vital concern was the hospital''s proximity to a residential area, demanding that the noise level of the generator be kept within strict limits. This requirement was successfully achieved during testing, with the noise level kept within 65 decibels at a distance of seven metres.

In addition to conducting a complete engine rewiring, Zest WEG also upgraded the generator controller, giving the customer improved ability to monitor the generator''s operation during load-shedding. The modern controls help protect the generator and optimise the lifespan of critical equipment.

Seventeen storeys and 30 000m2 floor space, the new Netcare Christiaan Barnard Memorial Hospital boasts a range of green design principles and technology which are in line with global standards –setting the benchmark for environmentally friendly hospitals in South Africa. Some of the solutions implemented include a special double-skin façade, which is expected to save around R120 000 annually, and efficient lighting instalments, which will see a 40% reduction in electricity used for lighting. Read on and see for yourself!

The building''s ''intelligent'' exterior façade comprises an external glass skin, with a void separating it from the building''s internal glass windows. This means that together, the internal glass windows and the exterior of the building act as a double skin, offering outstanding insulation to the interior hospital environment. The void within the two walls can be ventilated when the building needs to be cooled down, or closed to warm it up by means of louvres positioned between the two skins on roof level, which can either be opened or closed.

"The façade is also connected to wind driven extractors and motorised dampers which, in turn, are connected to the building management system. An intelligent and automatically controlled insulation layer enhances the energy efficient heating, cooling and ventilation technology installed in the building," says Dr Friedland.

"It works like a giant Thermos flask; with the façade forming an insulation barrier which ensures significantly less dependence on the air conditioning units in the hospital for maintaining ideal internal environmental conditions. At the same time, the glass façade has an attractive visual effect and patients and visitors are able to enjoy the magnificent views of the harbour, mountain or city scape, depending on where they are in the hospital," he explains.

Netcare''s environmental sustainability manager, Johan Durand says the building''s ''intelligent'' exterior façade is expected to save Netcare Christiaan Barnard Memorial Hospital some 105 000 kWh of electricity annually (about R120 000 per year in energy bills!)

The heating ventilation and air conditioning system that serves the new hospital is based on a rational design that exceeds South African national building regulations, and is based on an advanced standard as recommended and applied by the American Society of Heating, Refrigeration and Air Conditioning Engineers (ASHRAE). This allows for better filtration of air to further improve infection prevention and control, while offering greater energy efficiency. Further efficiencies will be achieved through using two water-cooled chillers housed on the roof.

A building management system (BMS) works to reduce the building''s cooling and heating requirements by means of a centralised control of all services within the hospital. "The system focuses on integrating all systems within the building into one environment to ensure that they all operate cohesively and to optimum efficiency," adds Durand.

The BMS system also measures the air temperature along sections of the façade and controls the motorised dampers to either extract or trap warm air depending on climatic conditions outside. The facility''s heating, ventilation and air conditioning system services the internal environment through variable air volume systems. These can be ramped up or down depending on the specific requirements of each individual ward.

The piping system has been designed in such a way that domestic hot water can be circulated throughout the entire building, thereby reducing wastage due to hot water being available close to the points of use. The domestic hot water integration with the air conditioning is expected to save 34 300 kWh of energy annually.

"We are effectively harvesting every little bit of heat energy and re-using it as an additional form of energy. Previously, this precious resource would have gone to waste, but now we are able to harness it to good effect," says Durand.

The hospital is also equipped with a sophisticated grey water harvesting system, which channels waste water from the renal dialysis filtration plant and the autoclaves used to steam sterilise medical equipment, to the ablution facilities. "Grey water harvesting and re-use is expected to save about 3 204 kilolitres of water a year, " explains Durand.

"In addition, we have fitted low flow showerheads, which use half of the water of a conventional shower, and aerator equipped taps on all hand washbasins to reduce water usage. "Where these fittings have been used in other Netcare hospitals, they have achieved significant water savings."

Dry-type transformers: Two high efficiency dry type transformers, which are situated on the roof of the building, supply electricity to the facility and will contribute to electrical cost saving.

Green lifts: Regenerative lifts are helping to further drive down the 17-storey hospital''s energy consumption. Dr Friedland explains: "Also helping to reduce future energy costs is the mechanism underpinning the facility''s regenerative power lifts, whereby the force of gravity is allowed to do the work when the lift is descending, and the motors act as generators, supplying the energy into a power bank for utilisation when the lifts go up."

"Efforts to conserve water and electricity should be high on the agenda of each and every South African, and we are committed to limiting our impact on the environment and to the judicious and sustainable management of our natural resource consumption. Netcare''s sustainability strategy aims not only to enhance the robust financial performance of the group into the future, but also to help ensure the future of the South African environment. The group''s impact in the environmental arena has shown that these two objectives are not mutually exclusive," concludes Dr Friedland.

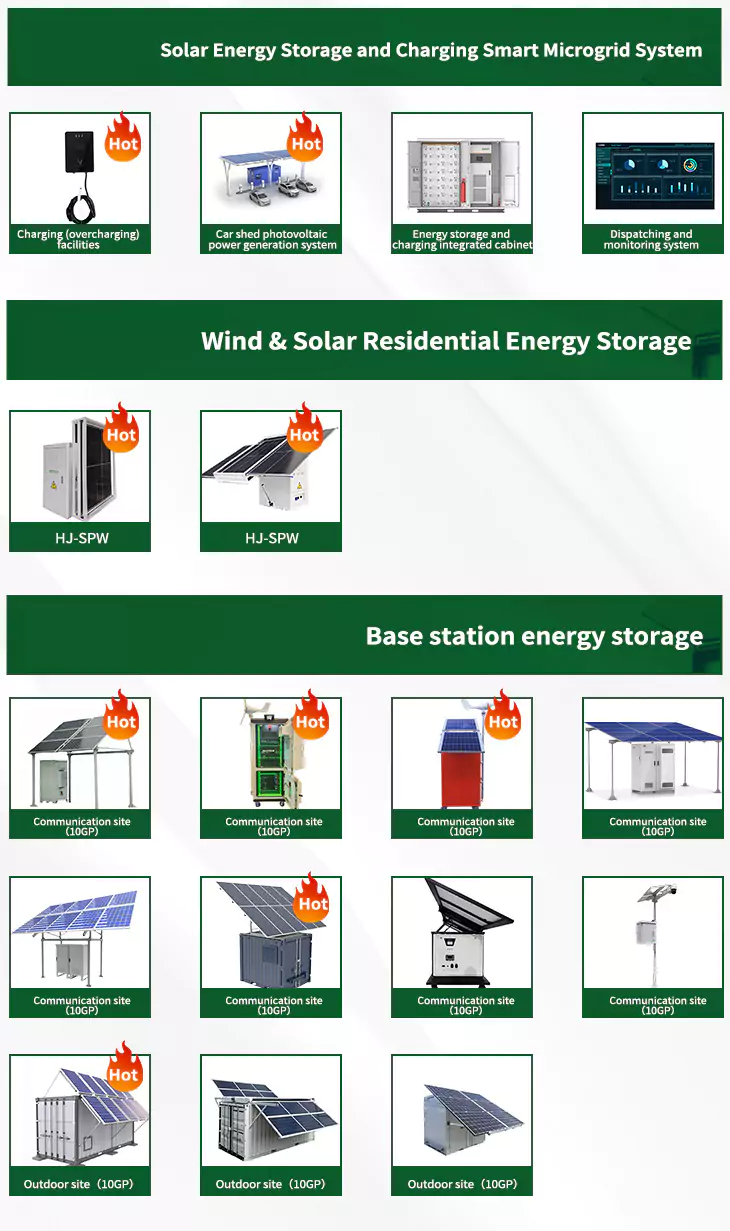

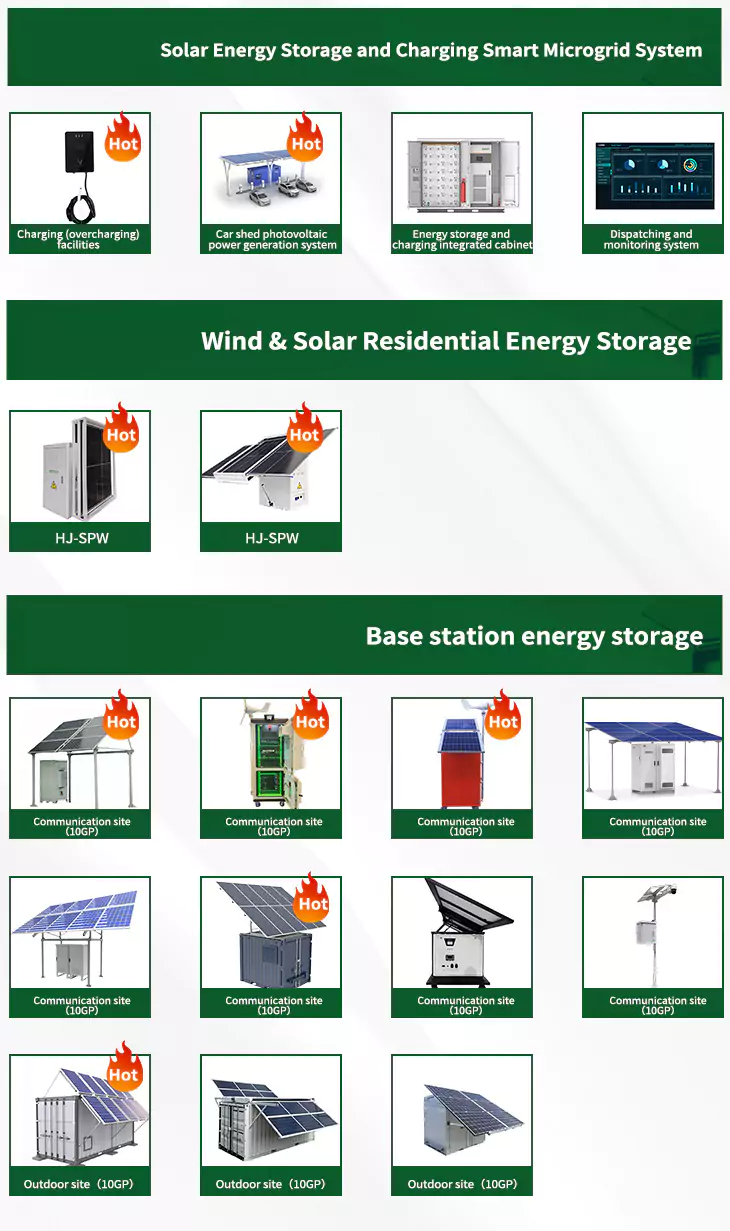

About Cape town hospital energy storage

As the photovoltaic (PV) industry continues to evolve, advancements in Cape town hospital energy storage have become critical to optimizing the utilization of renewable energy sources. From innovative battery technologies to intelligent energy management systems, these solutions are transforming the way we store and distribute solar-generated electricity.

When you're looking for the latest and most efficient Cape town hospital energy storage for your PV project, our website offers a comprehensive selection of cutting-edge products designed to meet your specific requirements. Whether you're a renewable energy developer, utility company, or commercial enterprise looking to reduce your carbon footprint, we have the solutions to help you harness the full potential of solar energy.

By interacting with our online customer service, you'll gain a deep understanding of the various Cape town hospital energy storage featured in our extensive catalog, such as high-efficiency storage batteries and intelligent energy management systems, and how they work together to provide a stable and reliable power supply for your PV projects.

Related Contents