Panasonic Energy Malaysia (PECMY) is the manufacturing division of Panasonic Solar business and it manufactures solar panel and integrated manufacturing of wafers, cells and modules. The only operating plant globally currently, it is located in the Kulim Hi-Tech Park which is located around 50km east of Penang, Malaysia. The plant was constructed in a record time of 9 months from planning to commissioning which represent a record in term of speed of construction of a large scale factory at the park.

The company was founded in 1918 as a producer of lightbulb sockets and has grown to become one of the largest Japanese electronics producers alongside Sony, Hitachi, Toshiba, Pioneer and Canon Inc. In addition to electronics, it offers non-electronic products and services such as home renovation services. Panasonic is the world's fourth-largest television manufacturer by 2012 market share.

Ditrolic Solar is a long-time partner of Panasonic group globally and has cooperated together on numerous projects in the Asian region. It is commissioned to build a solar rooftop system for the factory during its construction and work closely with its Japanese counterpart to seamlessly integrate the system on PECMY rooftop.

Osaka, Japan - Panasonic Corporation today started production at its newly-built solar module manufacturing facility in Malaysia. With an annual production capacity of 300 MW, the factory in Kulim Hi-Tech Park in the northwestern state of Kedah, will manufacture HIT® solar modules, which offer the world''s highest-level conversion efficiency. This new production facility will help Panasonic meet robust solar demand in Japan while further enhancing cost competitiveness.

The global solar market is expected to grow further with increasing environmental awareness and the introduction of stimulus measures such as feed-in tariffs and subsidies in various countries, including Japan.

Panasonic will take full advantage of this new facility, the company''s first fully-integrated solar manufacturing base producing from wafers to solar cells and modules, not only to meet such strong demand but also strengthen cost competitiveness through reduced transportation costs and use of local materials.

Panasonic is currently manufacturing HIT® solar cells at its two domestic plants and has three module assembly bases, two in Japan and one in Hungary, with an annual production capacity of 600 MW each of cells and modules. The new Malaysian factory will boost the company''s total solar module producing capacity by 50% to 900 MW.

Capitalizing on its solar manufacturing capabilities, Panasonic will step up efforts to provide integrated solar solutions combining modules with power conditioners, solar tracker bases, storage batteries and other components to meet the needs of diverse customers and expand its business.

Panasonic Corp announced it will withdraw from the solar manufacturing business due to fierce competition from its Chinese rivals. According to a report from Nikkei Asia, the company will end manufacturing of solar cells and panels at its factories in Malaysia and Shimane prefecture in Japan by March 2022.

The move marks a complete exit from the solar manufacturing business. The Osaka-based company had earlier announced that it was pulling out of a partnership with Tesla to produce solar panels at a factory in New York state.

Panasonic’s solar module manufacturing factory in Kulim Hi-Tech Park, Kedah was established back in 2011. It’s main purpose was to manufacture HIT (Heterojunction with Intrinsic Thin-layer) solar modules. The factory was used by Panasonic to meet the robust demand for solar products from around the world.

However, Nikkei Asia reported due to the increased production by Chinese manufactures, the price of solar panels has fallen to about a third of 2012 prices. The lower prices from China forced struggling Japanese players like Panasonic out of the business.

“We are considering various measures to strengthen the management structure of the solar business but at this point, nothing has been decided,” the company said in a statement. It added that the Nikkei report was not something the company had officially announced.

With Panasonic exiting the scene, this leaves Kyocera and Sharp as the only major Japanese companies that are producing solar batteries and panels. Much of the global share is now dominated by Chinese manufacturers like JinkoSolar, and it looks like the Japanese makers who once led the market are continually losing ground.

Panasonic today announced its plan to establish a company in Malaysia that will serve as Panasonic''s new solar manufacturing base. Panasonic Energy Malaysia Sdn. Bhd., to be set up next month, will operate a vertically-integrated solar manufacturing facility producing from wafers to cells and modules. Panasonic will invest 45 billion yen in the facility, which will start operation in December 2012 with an annual production capacity of 300 MW.

With environmental awareness increasing globally and introduction of subsidy systems and Feed-in Tariff schemes in Japan as well as other countries, etc., the solar cell market is predicted to grow further. Robust demand is expected particularly in the residential sector, the main target of the Panasonic HIT® (Heterojunction with Intrinsic Thin-layer) solar modules. The new factory, to be built in the Kulim Hi-Tech Park in Kedah, will not only help Panasonic meet this growing demand, but also strengthen the HIT module''s cost-competitiveness with the vertically-integrated production.

Panasonic will sell its solar modules as an individual product as well as part of a system combined with storage batteries. Further, as part of Panasonic''s comprehensive solutions business, which is built on capacities brought together across the Panasonic group companies, Panasonic will accelerate its solar business development globally.

TOKYO: Japan's Panasonic Corp will cease production of its own solar panels, national broadcaster NHK and the Nikkei newspaper said on Sunday, citing increasing price competition from Chinese manufacturers.

The Japanese brand will continue to sell third-party-made modules under its brand in its home market, as it already does overseas, but in-house PV wafer, cell and module production will halt by the end of fiscal year 2022.

About Panasonic solar panels malaysia

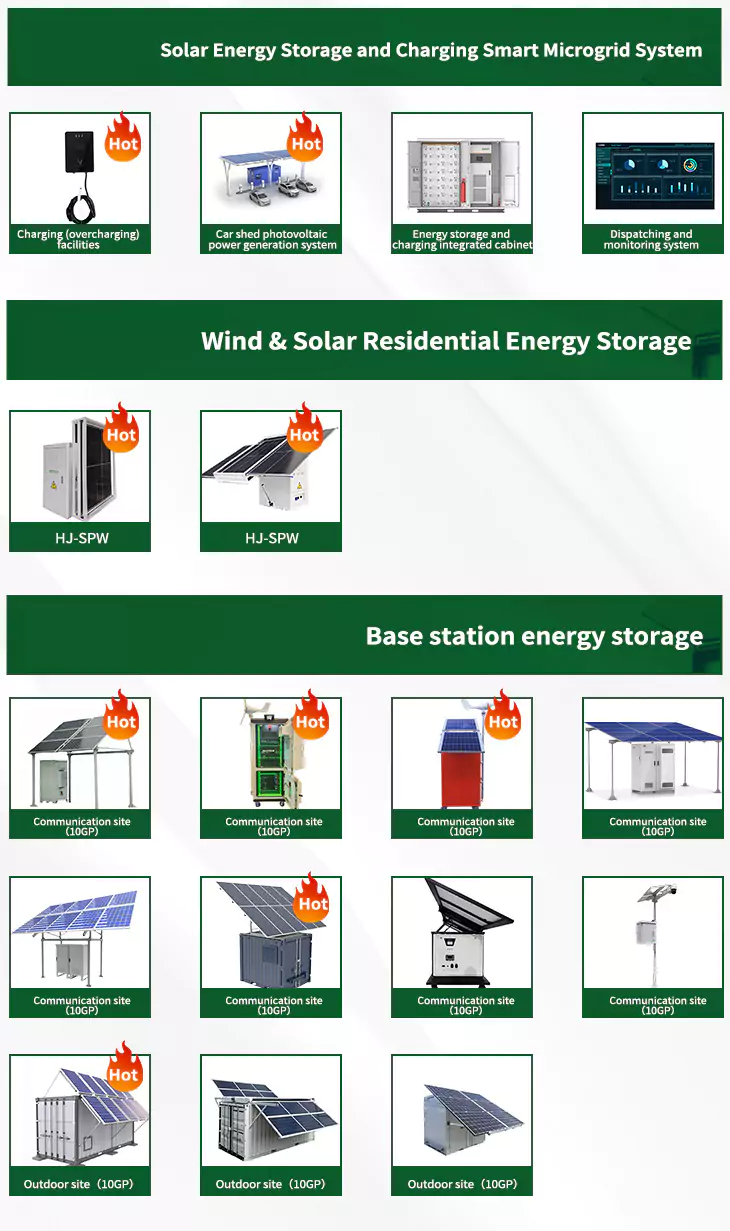

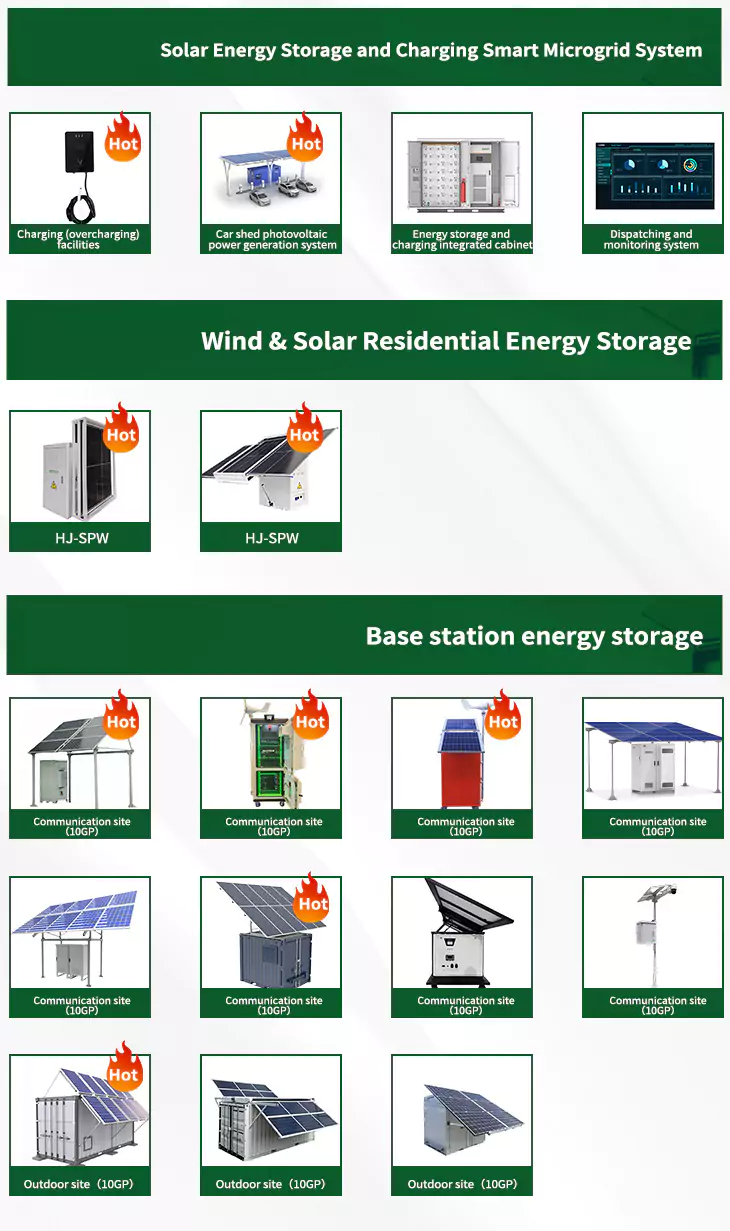

As the photovoltaic (PV) industry continues to evolve, advancements in Panasonic solar panels malaysia have become critical to optimizing the utilization of renewable energy sources. From innovative battery technologies to intelligent energy management systems, these solutions are transforming the way we store and distribute solar-generated electricity.

When you're looking for the latest and most efficient Panasonic solar panels malaysia for your PV project, our website offers a comprehensive selection of cutting-edge products designed to meet your specific requirements. Whether you're a renewable energy developer, utility company, or commercial enterprise looking to reduce your carbon footprint, we have the solutions to help you harness the full potential of solar energy.

By interacting with our online customer service, you'll gain a deep understanding of the various Panasonic solar panels malaysia featured in our extensive catalog, such as high-efficiency storage batteries and intelligent energy management systems, and how they work together to provide a stable and reliable power supply for your PV projects.

Related Contents